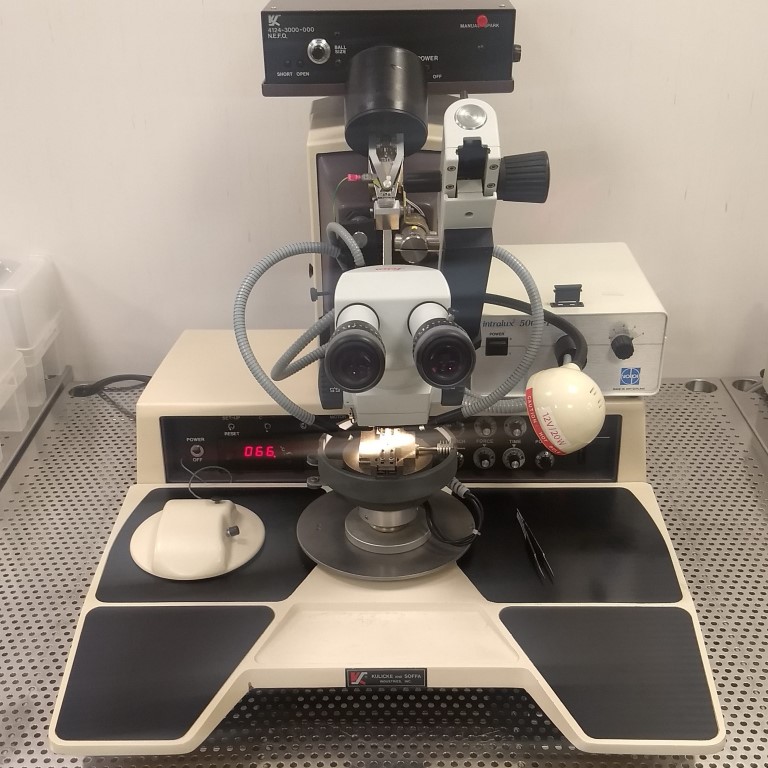

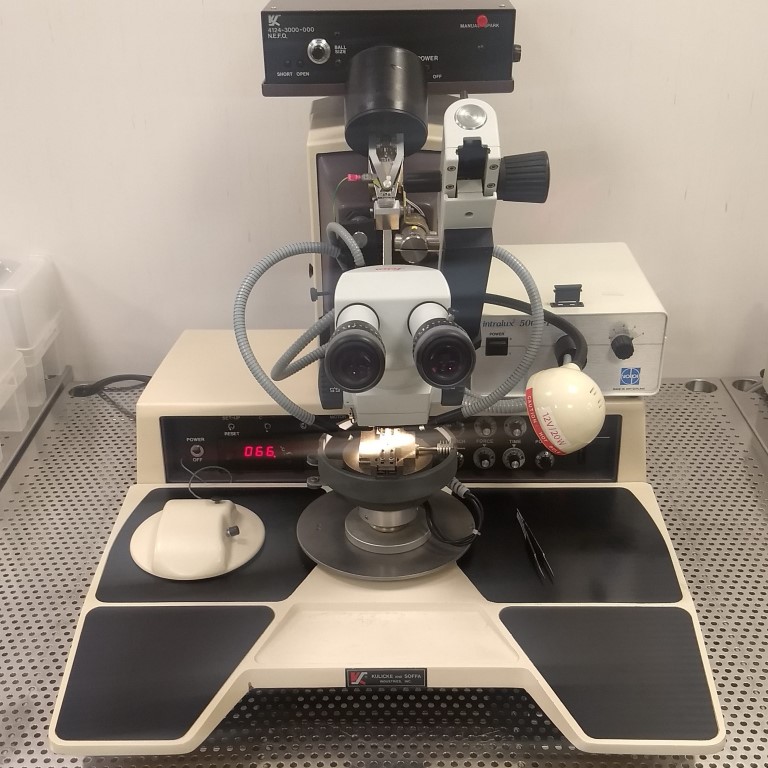

Ball Bonder – Kulicke & Soffa 4124

Details

Description

The Kulicke & Soffa 4124 Universal Ball Bonder provides reliable interconnects between a device and a package using a thin gold wire, on a variety of materials. We currently use gold (best) and copper (needs cleaning) as pad materials. Typical applications are electrical access to microscale and nanoscale devices and optoelectronic and microelectronic packaging. Parameters can be set independently for the two bonds and operation is Semi-Automatic or Manual. Operation of the machine is staff-only. Test samples are needed to optimize process.

Working principle

Uses a combination of heat, pressure and ultrasonic energy to make a weld at each end of the wire. Ball bonding requires that the first bond be a ball type bond and the second bond be a capillary wedge bond. Wire feed is at 90°. The minimum weld dimensions are around two times the diameter of the wire and the typical inter-bond length is less than a centimeter. Better if there is small height difference between sample and package. The bonding area is 95×95 mm2.