Overview

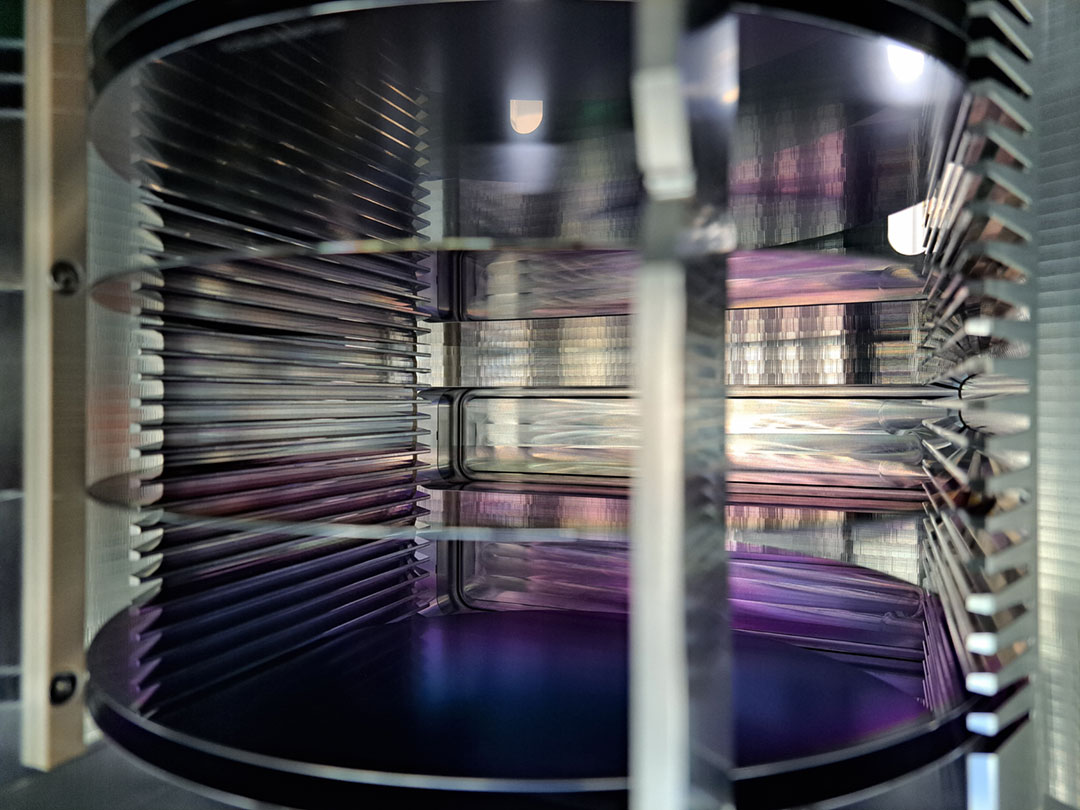

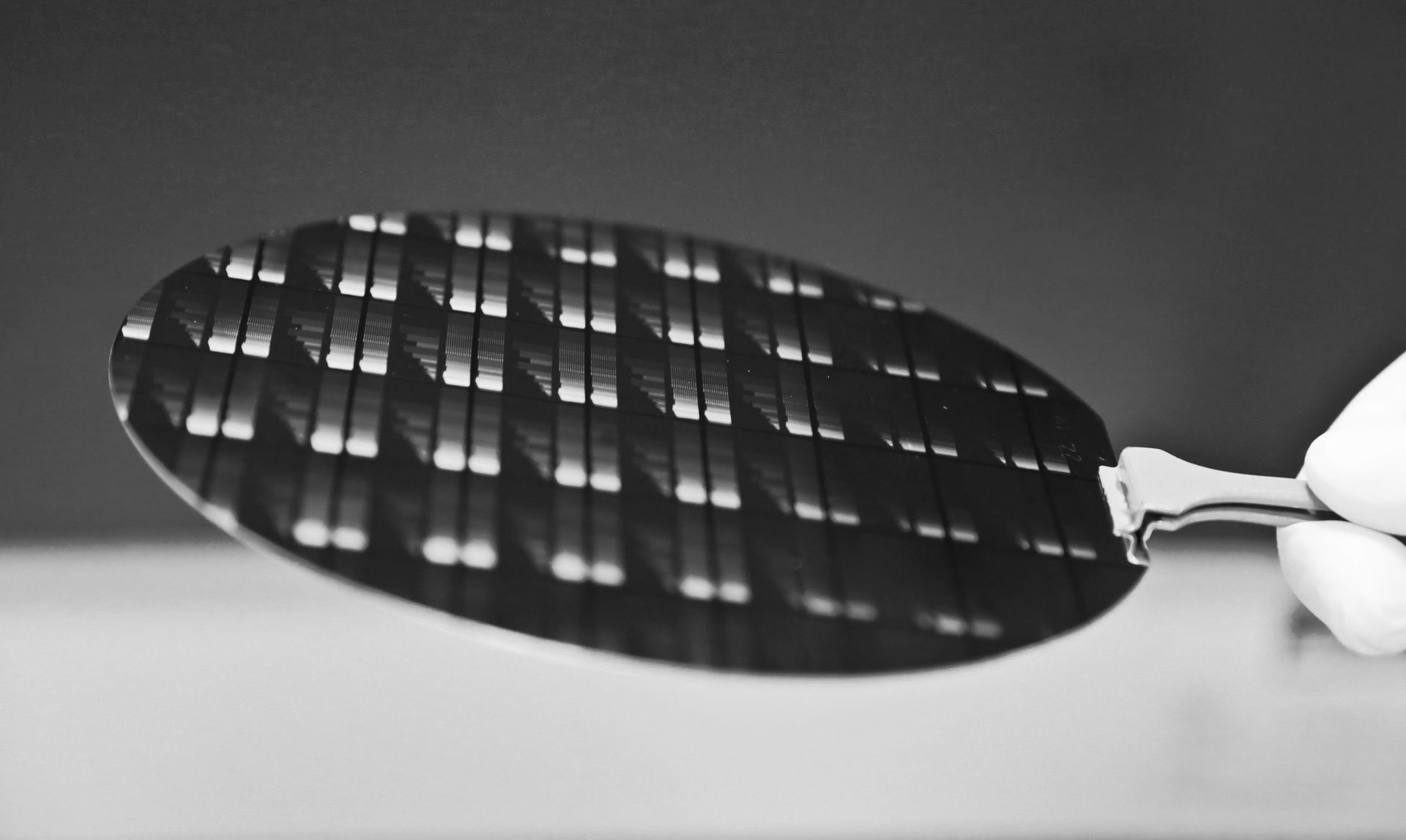

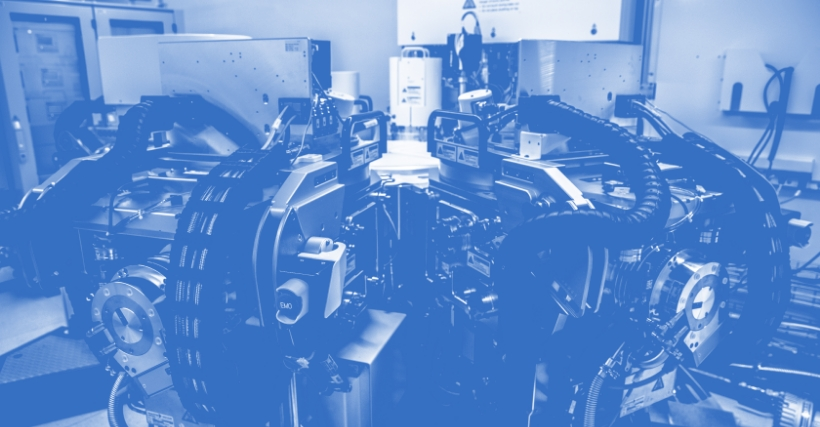

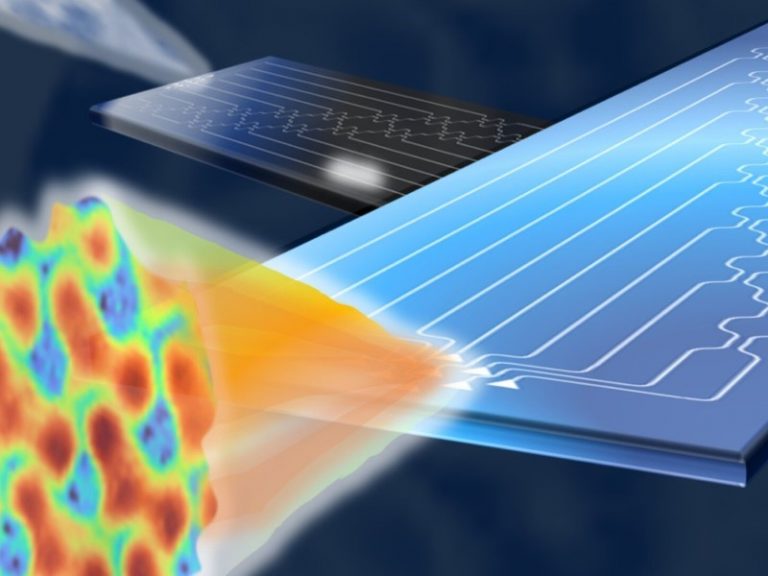

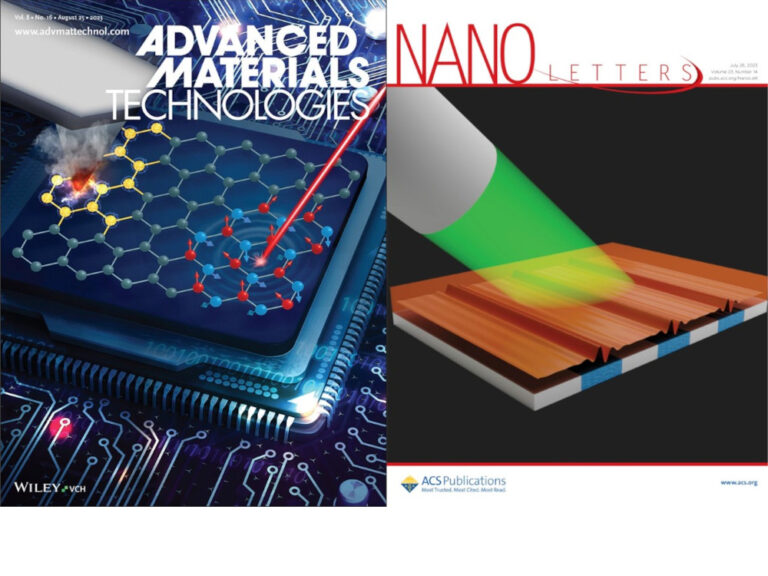

Polifab is the micro and nano technology infrastructure of Politecnico di Milano, created to provide the highest technological standards for a wide range of applications: photonics, micro and nanoelectronics, MEMS, biotechnologies, advanced materials and nanotechnology. Polifab is open and acts as an aggregating center for academic researchers, start-ups and companies.