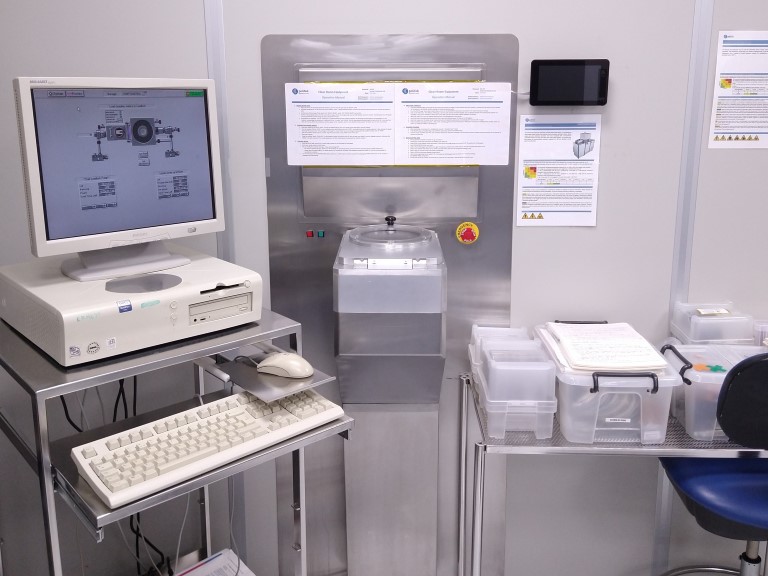

Spin Rinser Dryer – Semitool

Details

Description:

Spin Rinse Dryer is the world standard for high-performance cleaning, rinsing and drying. It features spin rinse and drying capability in one chamber. The Spin Rinse Dryer sprays DI water through a dedicated rinse manifold. DI water is constantly replenished on the wafer surfaces. DI water is purged from the process chamber using N2. During the dry portion of the process, heated N2 is applied through a separate dry manifold in the process chamber. The chamber is operated by its own programmable controller which accepts user recipe inputs. These inputs are retained in recipe memory utilizing a 2K battery backed-up RAM. The machine activity is displayed on the controller LED. Recipe creation and editing is accomplished via soft keys and inputs are displayed on the controller LED. Built-in interlocks prevent accidental opening of the chamber door during the process.

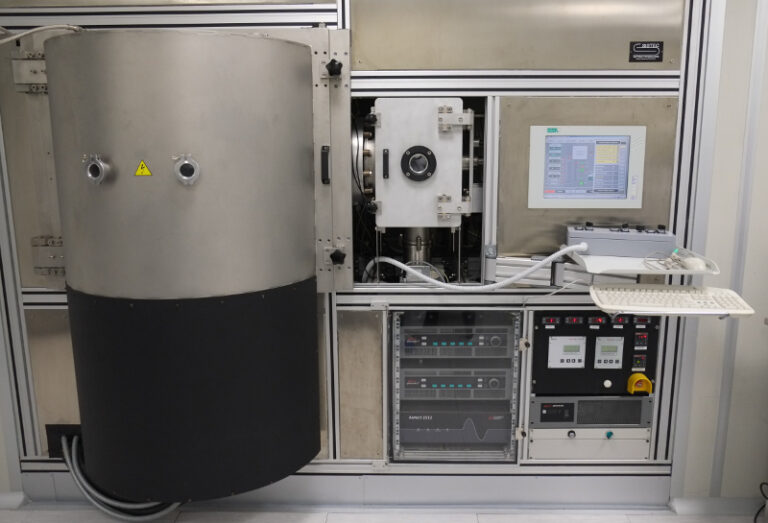

Working principle

The original Spin Rinse Dryer concept is simple. A single cassette of wafers is placed in a stainless steel rotor. The wafers are centered just off the axis of rotation, and rotated at high rpms so that centrifugal force “locks” the wafers in place to prevent tumbling and subsequent particle generation.

Specifications

- Wafer size: 4 and 6 inches

- Nitrogen: 113-70 l/min, 2.1-2.5 Bar

- DI water: 5.7-7.6 l/min, 1.8-2.1 Bar, 0-18.2 MOhm

- Process step time: 0-9999 s

- Rotor: 2000 rpm max